Home of Brutus Ten!

Brutus 2.0!

Counter-recirculating Re-sparge System

Or, CRS...

So, though this system has had several names to date, my original premise has not changed. Even though my original idea was to build the next Brutus to be a 20 gallon yield, hence the 20 tag, I have decided that size didn’t matter. It all works the same and represents a “next step” from my current system... To some degree, this system is still in a quasi conceptual stage. I have had a lot of fun testing this concept using my current Brutus Ten as a test bed, and indeed there are a few actual dedicated Brutus 2.0 systems out there in perfect working order. To these friends that have built their systems using this approach, to you I say GREAT! This means that you have gotten down to making good beer and let your inhibitions about efficiency go out the window as you should have!

So from here on out on this page, I will basically reprint from my original Brutus 20 page as I don’t feel like retyping it all, and I have a pretty serious Farmville session going on...

Concept…

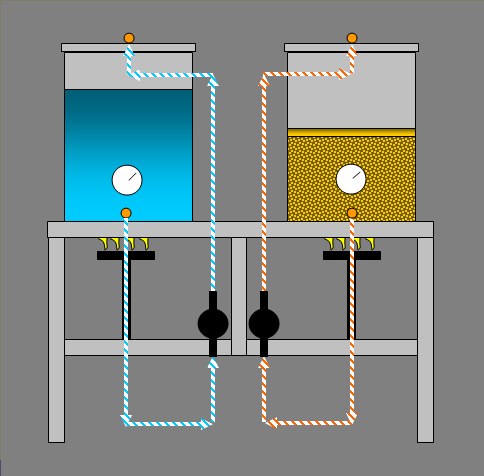

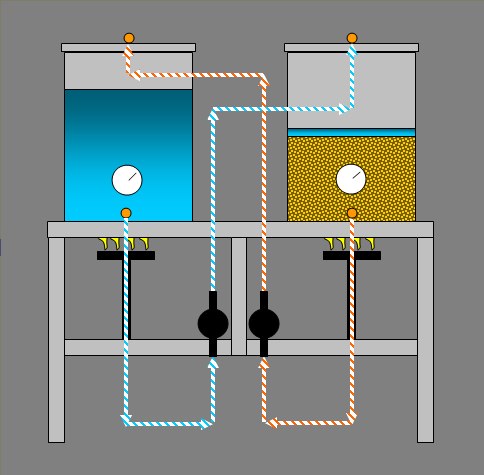

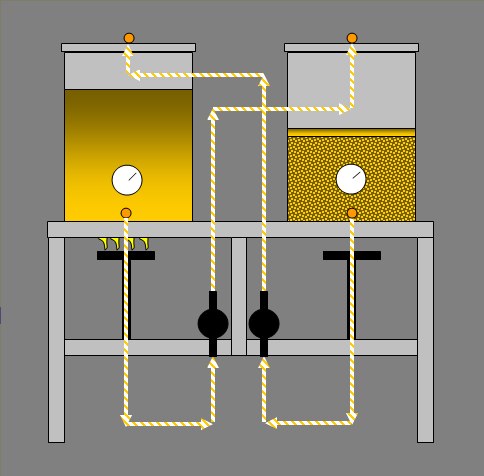

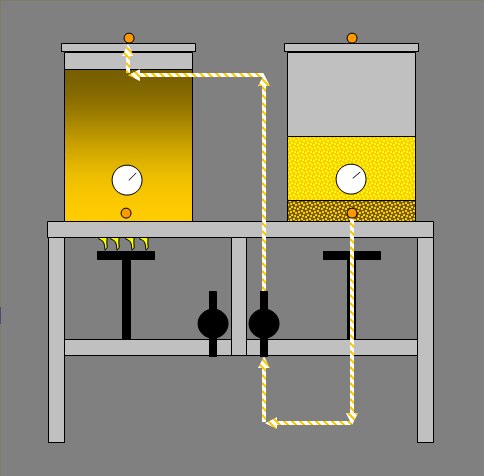

So what’s in a concept? Brewing with only two pots is relatively easy; actually easier, as I will explain. Too there are many benefits to this method I have found. This two pot method may not be cheaper, as in any single tier system a pump or two is required, and in a two tier, at least one pump will be required using this method. Basically as you can see in the diagrams, the system utilizes cross recirculation. After the normal mash resting period and the HLT/kettle is heated to 168/170 mash-out temp, the flow rates can be set in the mash tun and the HLT/kettle. The flow rates in each are set to a very slow trickle, each recirculating back to itself at this point. Once this rate is constant between the two, you can simply switch lids. Now the HLT/kettle water is flowing gently over the grains in the mash tun, out of the mash tun and back to the very same supply from the HLT/kettle. The HLT/kettle water will slowly become the wort. In the end, all will equalize between the two pots and all will be one in harmony! Recirculate the system until you are satisfied that the OG is the same anywhere in the system; HLT/kettle or mash tun, it will eventually equalize. In my system, 45 minutes is plenty of time to accomplish equilibrium and planet alignment.

Benefits…

Indeed your efficiency will be slightly less than fly sparging utilizing this method. Not really a benefit per say, but no more or so less efficiency than batch sparging in general. I have bumped my efficiency down from my normal fly sparging using traditional methods of 78% back to about 74% or so. This is no real deal to me anyway as anyone who knows Lonnie Mac, knows that I can give a rat’s butt about efficiency! This ain’t a grain race here; it’s about beer man! I collect the sugars that my recipe needs and no more. As far as PH, as we know during a long extended fly sparge the PH will rise. Much over 6.0 and we start to see astringency. This method utilizes the benefit of batch sparging in that respect. Likewise, I won’t be stripping my grain of every sugar molecule as this is not my intention. Let’s face it. I am a fly sparger from way back; pushing the limit, I have over-sparged a time or two like most have or will at some point. This method combines the two traditional sparge methods, in essence, a culmination, giving us a continuous batch sparge without the work involved, continuous natural grain bed filtration, slams the hammer down on PH and over-sparge astringency problems, heating of the wort can begin sooner too, in effect increasing efficiency during final recirculation sparging, the benefit list goes on…

This illustration shows Brutus 20 all set up at the beginning of the brew day. Pumps recirculating among themselves, HLT/kettle water heating to 170 and the Mash maintaining my preset mash temp for 1 hour. Both are recirculating VERY slowly and each flow rate is matched.

After an hour long mash, HLT/kettle water heated, the lids are switched to allow the HLT/kettle water to gently flow into the mash tun, and the mash to gently flow into the HLT/kettle.

This diagram represents a 1 hour recirculation sparge, when ALL things are at total equilibrium and all OG readings are the same no matter where you take it in the system.

After equilibrium, the remaining sugars can be pumped from the mash tun to your recipe volume. Then top off water can be added and the brew day begins!

So there we are! Don't b afraid to try new things man! We are only 10,000 years into beer. There are thousands of years left to go! Things are bound to change!!