BRUTUS "Ten" Build Pic's

A truck load of stainless steel... Two 20' sticks of 304 stainless 2" X 2" X .120 wall X 20'. I had them cut each one in half so I could get them home safely. Amazingly enough, this stuff looked like GREAT quality, and had Made in China stamped all over it...

Couldn't cut them to size any other way at the time. A friend of a friends allowed me and my original friend to enter a rather large factory here in Houston and let me use their diamond cold saw. This made quick work of these cuts. Here they await clean-up...

Filing away. Just basic clean-up work...

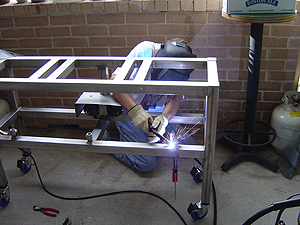

Tacking up the frame. Just enough tacking to get the whole frame together and standing. This was a BIG hassle. The worst environment to weld on is a crooked patio! This was the biggest problem in the whole project. I overcame it by making a level bed using a few 2" X 4"'s and some screws.

One side all tacked up...

The sides. Again, keeping things square was key...

The new Hobart 180 MIG and a bottle of Argon.

Taking shape! I am almost scared!

Tacking in the top supports for the pots...

Again...

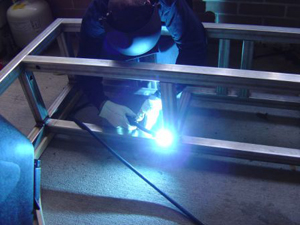

Driving her home big boy... A full weld-out in a day. I am having a total BLAST doing this project, and all confined on a dinky apartment patio.

Welding inspector makes her rounds...

My Son was a very big help in all of this. He brushed many welds and did allot of grunt work.

More weld-out.

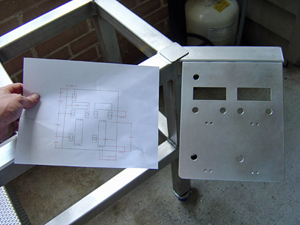

Tacking on the control panel mount. All cut and fitted by hand...

Driving it home...

Almost done. A few welding details are all that remains...

Welded...

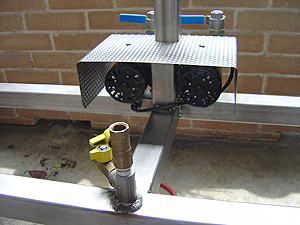

The pump mounting...

Decorative stainless pump shroud.

The control panel drilling is completed...

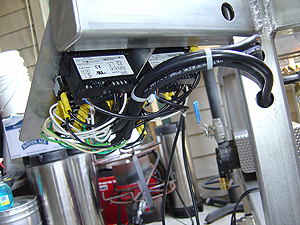

Wiring is completed...

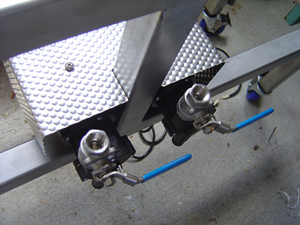

Gas beam fittings are welded on and pressure tested.

...